By the end of 2024, the Defense Forces will receive about 2 million FPV drones. This will make their impact and role on the battlefield comparable to that of classical artillery. However, their supply may be in jeopardy as China has begun restricting exports of drone components, which could undermine our country’s defense capabilities.

Leading Ukrainian manufacturers are already experiencing the impact of these restrictions and are seeking alternative solutions to maintain purchases. Meanwhile, Bloomberg reports that the Chinese government’s actions are likely just the beginning, with broader export restrictions on drone parts potentially being implemented as early as the new year.

Given the critical reliance and significant demands of the Ukrainian army, the issue of establishing local production becomes increasingly pertinent. This would not only ensure a predictable supply chain but also reduce dependence on the precarious partnership with China. However, the question remains: is Ukraine equipped to manufacture electronics and other necessary components domestically?

What does an FPV drone consist of?

To grasp the issue fully, it is first necessary to understand what a conventional drone consists of. The core of any FPV drone is its frame, which serves as the foundation for all key system components: motors with propellers, cameras, antennas, signal transmitter and receiver, flight controller, and speed controller.

The flight controller is the “brain” of the drone. It executes operator commands and keeps the copter in the air. With the help of a built-in barometer and accelerometer, it determines the position of the drone, how it changes due to atmospheric phenomena, and compensates for their impact by stabilizing the platform by adjusting the speed of each individual electric motor.

Drone control is made possible by the coordinated operation of the modules as follows: the radio signal from the operator’s console is transmitted to the receiver antenna, which sends the received command to the controller. The latter sends it to the speed controller, which transforms the signal into a change in the voltage supplied to the motors.

The video image captured by the camera is transmitted through the controller (adding information about the flight altitude and battery charge) to the signal transmitter, which transmits the image to the operator via an antenna.

All of these components are currently mostly sourced from China, but the Ukrainian market is not standing still and is joining the competition, gradually increasing supply and delivery volumes.

Localization of production

One of the leading companies engaged in localized drone production is the Ukrainian company Vyriy Drone. Today, it mass-produces 10-inch FPV copters that consist of 70% Ukrainian components!

The company’s journey toward the Ukrainianization of production started in the spring of 2023 with an order for a batch of carbon frames—one of the simplest components—from a local manufacturer. Contract manufacturing proved to be the optimal solution, enabling the use of existing facilities and experienced specialists without the significant expense of establishing a dedicated enterprise.

The decision to switch to Ukrainian parts proved to be profitable, so a few months later the company ordered propellers. Their production is simple and was carried out at one of the many Ukrainian plastic goods manufacturing companies using injection molding machines (automated machines for injection molding plastics into special shapes.)

“Their production is not complicated, as there is a very simple two-component mold. There are certain specific requirements, because the shape of the propeller must be precise, and it must be centered. Now there are more than a dozen, if not several dozen, [such] manufacturers in Ukraine,” says Oleksiy Babenko, the company’s founder.

Producing in Ukraine proved more expensive than sourcing Chinese-made parts, but it ensured consistent, high-quality components. This decision paid off swiftly when a shipment of Chinese propellers arriving in late fall turned out to have a 90% defect rate! Without the prompt replacement of these with Ukrainian-made propellers, drone deliveries to the military could have been severely disrupted.

A key milestone that set the company apart from dozens of other FPV drone suppliers was the launch of its own electronics production at Ukrainian facilities. Vyriy Drone began by developing flight controllers and speed regulators, whose designs remain relevant despite technological advancements, unlike communication receivers (ERLS). The company created technical documentation for producing controllers and regulators tailored to military needs, integrating them into a unified two-board design known as the “flight stack.”

In late fall 2023, the company ordered several hundred test stacks and receivers. This testing phase helped identify issues and refine the design for improved performance. And in early 2024, the developers received the first production batch of 5000 sets.

“Producing our own receivers freed our hands and provided better communication. The Chinese systems were only able to operate at 900 MHz. Yes, you can shift the frequency there programmatically, but since the output stage is designed to transmit the signal best at 900 MHz, replacing it with our own module was the best solution,” say Vyriy Drone developers.

The production of receivers has given the company a key military advantage: it can now change the operating frequency for a new batch in just one day, allowing it to quickly adapt to the emergence of new Russian electronic warfare systems. As a result, the company was the first to mass-produce drones with 500 MHz communication after the basic 700-1000 MHz began to be massively suppressed at the front lines.

The first batches of electronic components were significantly more expensive than their Chinese alternatives, but over time, Vyriy Drones managed to reduce the cost by optimizing processes and electronics design. For example, flight stacks have reached a market price of $40 per item.

The company said that they managed to reach a competitive price without compromising quality, and local production allowed them to keep the defect rate at an extremely low level of 1-3% and solve problems quickly. At the same time, Chinese electronics suffered from the same chronic problems: lack of predictability of supply and a large number of defects.

“For example, when the Chinese celebrated the New Year, many customers did not receive their components, but we were fine and had enough [orders]. Since then, we have completely switched to our own electronics and continue to work on it,” says Oleksiy.

Currently, there are about five companies in Ukraine with expertise in producing electronic components of the required size and purpose. These companies still rely on some Chinese-made parts, such as microchips and other basic elements like transistors. According to the manufacturers, there is no need to completely abandon Chinese components in this niche, given their widespread use in the consumer sector and their sufficient quality. In fact, the sale of such components cannot be banned.

A good example of the availability of the component base for FPV drone electronics is the STM32F405 chips, which are used to make flight controllers. Their production is deployed in China, Japan, and the United States. Their sales cannot be limited due to the wide range of applications, which include everything from refrigerators and washing machines to children’s toys.

The example of the production policy of Vyriy Drones shows that independent production of drones is a reality. However, some Ukrainian manufacturers have different views concerning the current component market.

One of these companies is Wild Hornets, which supplies several lines of FPV drones to the Defense Forces on a large scale. In the production of their 10-inch copters, only 15% of the components are of Ukrainian origin, primarily consisting of the simplest mechanical parts.

The company’s co-founder, Yuriy, said that, according to his estimates, current Ukrainian solutions do not meet the required standards, in particular, due to low performance and quality. Another factor he cites is the small production volumes that do not allow for a full transition to their use.

Despite this criticism, he views localization as a priority, acknowledging the critical dependence on Chinese goods. The company has already faced supply issues due to Beijing’s restrictions on drone component imports.

“In the future, we will definitely increase our level of localization. We are critically dependent on the supply of engines, video transmitters, cameras, and stacks. We have made good progress in the area of regulators and flight controllers, and I do not rule out that next year we will be seriously competing with Chinese-made components,” Yurii said.

In one of its latest developments, a large 15-inch Queen Hornets drone, the company already uses locally produced flight controllers and speed controllers. According to the developers, the number of Ukrainian components in it has reached 65%, partly due to the lack of necessary solutions in China.

Does a fully Ukrainian drone already exist?

The Ukrainian industry has already taken the first steps towards localization, but drone production still heavily depends on the following components made in China: electric motors, communication modules, and cameras. This may change in the foreseeable future, as Vyriy Drone has recently assembled its first prototype FPV copter entirely from Ukrainian-made components.

The assembled prototype received a Kurbas-256 thermal imaging camera produced by Odd Systems, a video transmitter by D1, and motors by Motor-G. Its technical specifications are on par with those of its Chinese equivalents, but it offers significant advantages in communication stability and video quality.

The developers say that the cost of the prototype is UAH 21,000, but it will be lower if a large series is produced. For example, the wholesale price of a 10-inch Vyriy-10 drone does not exceed UAH 17,000.

It is also important to understand that drones produced in Ukraine are designed specifically for the military, which the Chinese market cannot fully offer. It’s about both reaction time and design: combat copters have specific requirements for communication systems and cameras, and need connectors for additional equipment such as initiators, fuses for explosives, and an automatic target acquisition system.

The local companies manufacturing key components are just beginning mass production, so it is only a matter of time before Ukrainian drones become widely available.

Development of critical areas

Militarnyi reached out to Ukrainian motor and camera developers to evaluate the feasibility of eliminating reliance on China in this niche, both currently and in the medium term.

The sources involved in electric motor production stated that China is currently the primary and, in practice, the sole supplier of products for drones and unmanned aircraft in general. A Ukrainian manufacturer, Motor-G, a pioneer in this field, is only now preparing to launch its own line of engines.

The Motor-G team has already completed preparations for the start of production, having successfully tested prototypes, as well as selected production equipment and the necessary personnel. At this stage, the company offers rather modest delivery volumes of up to 20,000 motors per month, which can grow to 60,000 units with the growth of orders. These figures should be divided by four to understand the number of potential “Ukrainianized” FPV drones.

“These motors are designed and manufactured in Ukraine. In terms of localization, the Ukrainian component is 70%, the rest is imported from abroad. The main Chinese element is neodymium magnets, the world monopoly on their production belongs to China. But this is not critical, as they are widely used in the civilian industry,” says Oleksiy Hrebin, CEO of Motor-G.

The situation with cameras for drones remains more complicated. There are two manufacturers of thermal imaging modules in Ukraine—SeekUAV and Odd Systems—that rely on Chinese-made lenses and matrices in their designs. Today, they have no alternative in a niche that requires high-quality and, at the same time, the cheapest possible components. The specifics of the product make it possible to really limit their exports in the event of global sanctions.

Both companies have one product each in their portfolio, namely analog thermal imaging cameras with a resolution of 256×192 px: SeekUAV-256 and Kurbas-256. Both products consist of the aforementioned lens-matrix unit operating under the control of a microprocessor board and the corresponding software.

The production of key technical elements in Ukraine is not possible due to the complexity and huge investment required, so they focused on ensuring quality final assembly and developing proprietary software that would better realize the system’s potential and meet the needs of the military.

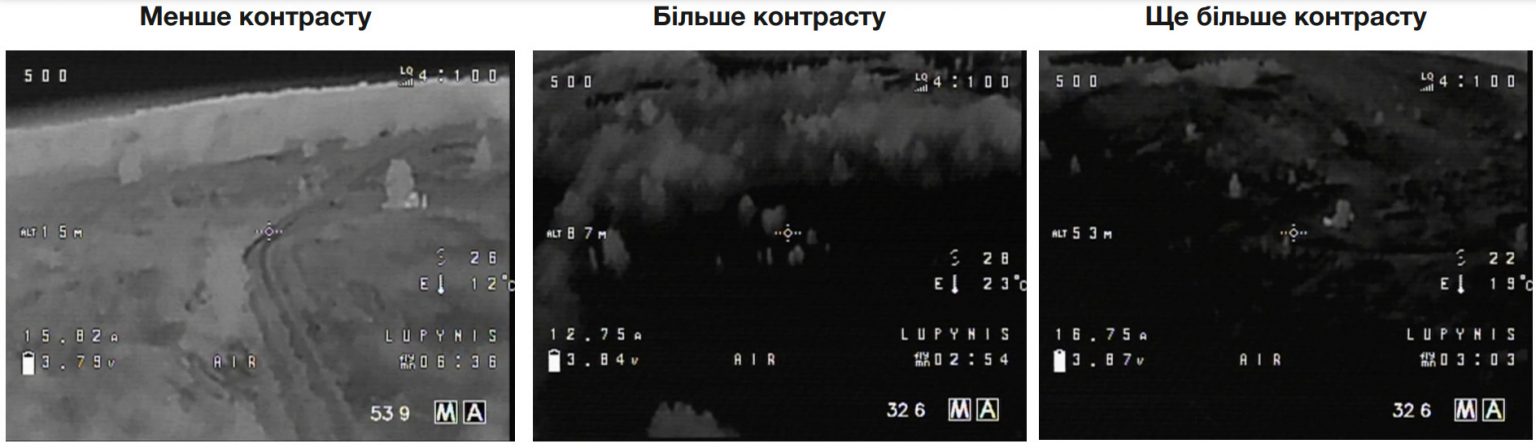

“Other thermal imaging cameras have an unpleasant quality—they freeze for a few seconds at regular intervals. It is clear that pilots do not like this. This happens because of the so-called calibration shutter, which is automatically activated—a design feature of all such thermal imagers. Due to the fact that we developed the Kurbas camera completely independently, we can control the operation of the shutter, making life easier for pilots,” says Andriy Tagansky, General Manager of OddSystems.

That is, the proprietary low-level software gives full control over the operation of the camera elements. Another example is the implementation of the ability for the pilot to change the contrast of the image right during the flight, which increases the probability of finding the target.

Due to production optimization and technical solutions, the Ukrainian manufacturer has managed to create cameras that are competitive with their Chinese alternatives. And it is about both certain technical advantages and cheaper products:

- The retail price of Kurbas-256 is UAH 10,000 ($240), and when ordering 500 or more, the price nears $225. If the volume increases to 5000 units, the price drops to 6,000 UAH ($150).

- A batch of 5 SeekUAV-256 cameras will cost UAH 11,000 ($260), a price per unit in a batch of 500 and above will cost $190. A batch of 5000 units will cost 5,900 UAH ($140) per unit.

For example, the cost of a comparable quality Chinese camera, CADDX-256, ranges from $170-250 in Ukraine.

In the current environment, SeekUAV and Odd Systems are not competitors, as even at full capacity, they can jointly supply only up to 10,000 cameras per month. Meanwhile, according to drone manufacturers, monthly imports in the thermal imaging camera niche alone range from 20,000 to 60,000 units.

However, both companies still remain depend on Chinese suppliers. SeekUAV is trying to change this situation by switching to an American component and matrix with a resolution of 320×240 px. The cost of the new camera will increase by 50%, and it is expected to be available not earlier than next year, but it will allow diversifying supplies and bringing the image quality to a much higher level.

The role of the state in the industry

Ukrainian defense companies have achieved remarkable success in the field of unmanned systems, and the significance of the one million FPV drones delivered this year is comparable to artillery ammunition. However, in such a critical niche, China today has more preferences than the national manufacturer!

In June 2023, the Ukrainian Parliament supported bills that abolished VAT and import duties on components, including those made in China, during martial law. While this was a correct and significant decision to support the defense industry, it now works against local manufacturers, as their product costs immediately rise by 20–30% due to the taxes they are required to pay.

To put it into perspective, in just six months of this year, from March to August, Vyriy Drone paid approximately UAH 100 million in taxes on the purchase of components. Meanwhile, Chinese manufacturers receive tax refunds after exporting their products abroad, and their importers are simply exempt from entry duties at the Ukrainian border.

In fact, the situation is such that Ukrainian manufacturers are encouraged to buy ready-made Chinese products, which are cheaper and don’t require investment in production. As a result, Ukraine, as a state, is losing foreign currency on millions of drones and hindering its own defense companies from progressing beyond basic assembly to the level of more complex technological solutions.

The co-founder of Vyriy Drone notes that, de jure, manufacturers have the opportunity to refund taxes paid, but in reality, it is almost impossible for a private company.

“Under the current conditions, it’s impossible: to produce a drone, you first buy raw materials (paying VAT), manufacture components (paying VAT), and then sell them to us for final assembly (paying VAT). To get the taxes back, a tax audit must verify all these transactions and confirm everything was done correctly. Then, if the [state] budget has money—and most likely it won’t—you might receive the VAT refund in six months. How realistic is this for a private company? It’s almost unrealistic, because even state-owned companies don’t always get a refund,” says Oleksiy.

However, even with taxation, some Ukrainian manufacturers manage to make components cheaper than Chinese ones. A significant role in this is played by optimization of production and logistics, as well as initial quality control and feedback from the manufacturer, which allow avoiding large volumes of defects of 10-15%, as is the case with Chinese components.

Given the government’s announced intention to double drone production in 2025, it should be primarily interested in reducing the tax burden and supporting local drone production to realize its ambitious plans. After all, localization may be the only alternative if China openly supports Russia’s war against Ukraine.

SUPPORT MILITARNYI

Even a single donation or a $1 subscription will help us contnue working and developing. Fund independent military media and have access to credible information.

Вероніка Грищенко

Вероніка Грищенко

Андрій Соколов

Андрій Соколов

Urich

Urich

Андрій Харук

Андрій Харук

Контужений Безпілотник

Контужений Безпілотник

Центр ініціатив ПЖ

Центр ініціатив ПЖ

Vadim Kushnikov

Vadim Kushnikov

Андрій Тарасенко

Андрій Тарасенко

Юрій Юзич

Юрій Юзич