Shahed-136 drones have become a symbol of Russian terrorism and night attacks in the Ukrainian sky. Until now, however, their production was under the cover of secrecy.

But on February 4, 2024, this situation changed when the PRANA Network hacker group announced the successful email hacking of the shell company Sahara Thunder, associated with the Islamic Revolutionary Guard Corps. The company, which mediated between Russia and Iran, had a number of documents at its disposal that shed light on the state of drone production and other important details related to it.

From the seized papers, it was possible to find out that in Russia, as early as April 2023, a factory was launched to assemble drones from Iranian spare parts. However, by 2025, it should switch to a completely closed cycle by manufacturing drones from Russian components.

The ‘Lodka’ (Boat – ed.) project to establish the production of strike drones, which costs RUB 108.5 billion, involves the construction of a plant and the production of 6,000 drones at its facilities over 2.5 years.

From the Militarnyi’s detailed report on the found documents, you will learn how Russia uses child labor, where the drone plant is located and how it is arranged, how much actually Shahed-136 costs and which drones the Russians plan to localize in the future.

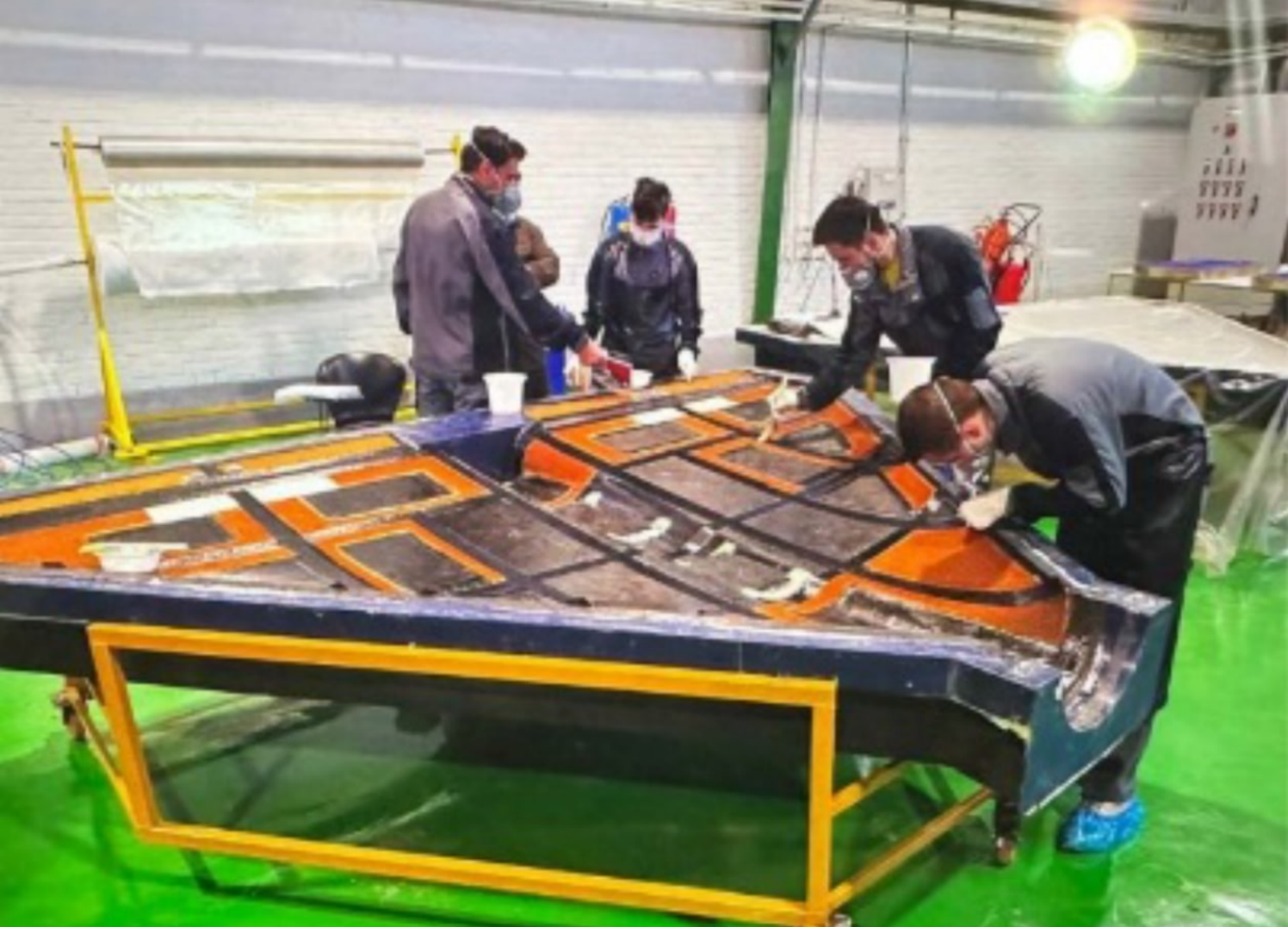

Drone Factory in Russia

In 2024, in the production of Iranian drones in Russia, a whole network of enterprises was involved, which were responsible for the production of mechanical parts, fuselage, certain elements of electronics, etc.

However, based on the published papers, we can conclude that the main contractors for the project were OEZ PPT Alabuga JSC and the company Alabuga Machinery. They were responsible for the final result and contacts with the Iranian side. This can be inferred from transactions for the payment of goods in which they act as the payer and final recipient.

At the facilities of Alabuga Machinery located in the special economic zone ‘Alabuga’ (Republic of Tatarstan, Str. Sh-2, building 5/12, room 110), the fuselage, engine, and work with electronics are carried out. A final assembly also takes place there.

The production complex valued at RUB12 billion ($131 million) is located on the basis of the Synergy industrial park, providing production space for the enterprise.

Alabuga was created as a preferential tax zone for localizing the production of foreign companies (3M, Ford, Air Liquide, Saint-Gobain, Drylock Technologies, etc.). With the imposition of large-scale sanctions, all these enterprises left the market. At the same time, the industrial base and all the necessary infrastructure had already been created, prompting the reformatting of the facility to meet new needs.

Based on the production commissioning plan, we can say that the work on the design of the enterprise, the supply of machine tools, and the deployment of production lines began in January 2023 and continued until April, when the first line from the major assembly was launched.

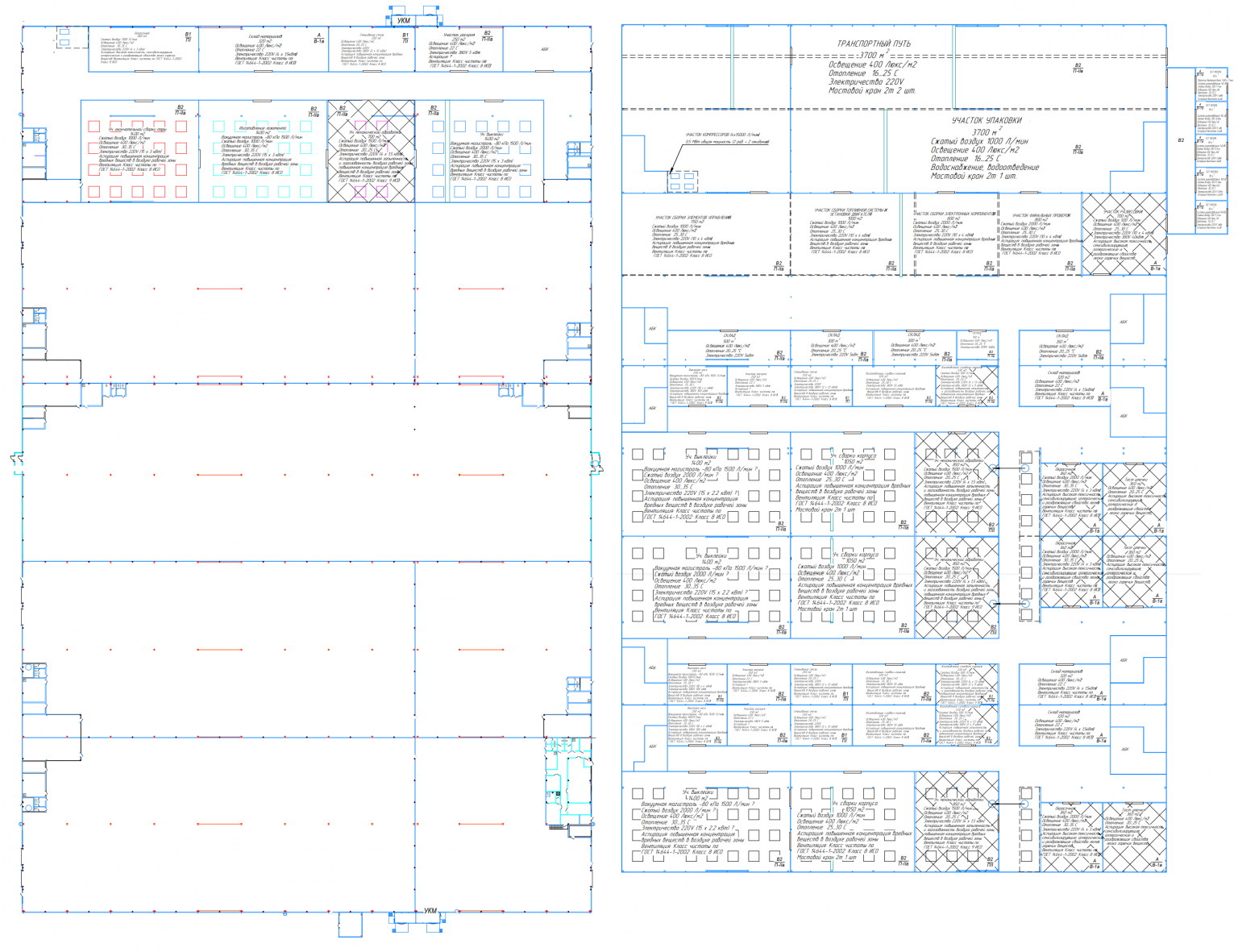

The production itself is located on several floors of the same building. It has three parallel fuselage production lines as well as a final assembly line where a fuel system, mechanical elements, and electronics are installed in the finished fuselage.

You can study the scheme of the enterprise in good quality at links 1 and 2.

Each line consists of several sections where a particular operation is performed. The order of the lines is as follows:

- The metal shaping department, where the carbon web is cut

- Bonding department, where the parts formation takes place

- Machining department

- Painting chamber

- The shop also has a warehouse with materials, a quality control area, and a final assembly department.

In the same building, on one of the floors, the production of MD550 aircraft piston engines and other mechanical equipment for drones was launched. This information can be confirmed by the plant plan found, as well as a separate application detailing the specified equipment samples.

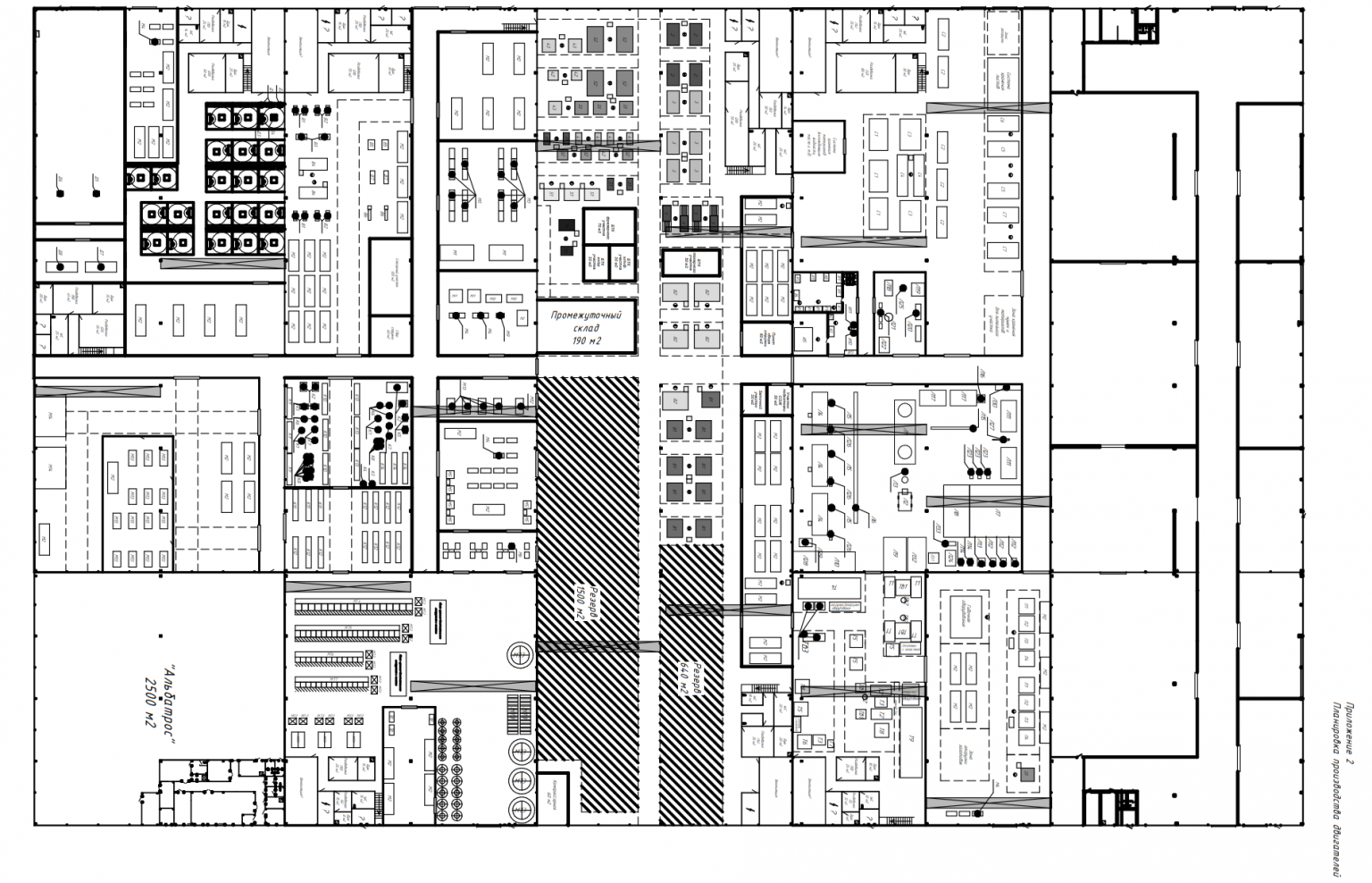

The facilities plan completely replicates the layout of one of the floors (left side) of the Alabuga Machines plant, as depicted above.

There is no further information about this object in the found papers. However, the plan is labeled ‘Albatross’—the same name as the Russian company that manufactures drones, which deployed its facilities in Alabuga in 2023.

‘Albatross’’s legal entity is registered at the same address as Alabuga Machines, which also confirms the version of placing enterprises in one building.

The found documents also indirectly imply the presence of a 10,000 m2 enterprise on the territory of the Alabuga economic zone, which works with electronic components and software for Iranian drones. But its exact location is not mentioned.

The Alabuga plant project includes a production cycle capable of producing 10 products per day with a three-shift mode of operation. According to plans, the annual production rate was supposed to reach 2,500 drones per year.

All drone production facilities were set up by the Iranian side turnkey within 4-5 months, based on existing infrastructure. Iran fully or partially transferred all the necessary equipment, including machinery, production lines, and assembly lines.

All machines on the lists that were sent to the Russian Federation are of foreign origin. In particular, there are products from Taiwan (Chiah Chyun CT2-52YM) and China. A number of others are labeled under the alternative name of the intermediary company (for example, “iMachine G-207”).

Shahed-136 Production and Cost

According to the agreement concluded in November 2022, in the future, Russia plans to completely localize the production of Shahed-136 drones over the next several years. In most documents, they are referred to under a special cipher as ‘Dolphin 632 type motor boat.’

Initially, the Iranian side announced the cost of each drone delivered – RUB 23 million per unit ($375,000). However, during the negotiations, an agreement was reached at the level of RUB12 million per drone in the case of ordering 6,000 units ($193,000).

The localization schedule provides for the transfer of production documentation and software on the day of payment of an advance of RUB 36 billion (the probable date is November-December 2022).

After that, according to the plan, fuselage production had to be established in Alabuga within 4 months (by April), partial production and assembly of finished components of engines and avionics – within 12 months (by December), and rocket-type launch systems and warhead – within 16 months (by April 2024).

During the first three months from the date of payment of the advance, Iran pledged to deliver 100 UAV per month, and over the next 27 months – 211 sets. In total, in 30 months, or 2.5 years, Iran must transfer 6,000 UAVs.

As of the end of December 2023, the Russian plant was supposed to produce 1,932 strike drones.

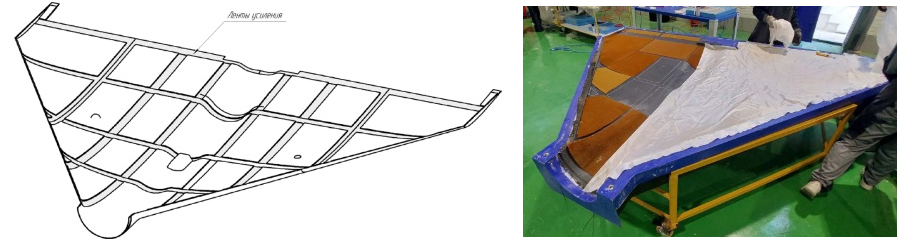

Among the files, production documentation was found, namely SOP documents—an archive of standard operating procedures, which, in fact, is an instruction for employees with a detailed step-by-step description of each stage of production.

In particular, they describe the full production cycle of all elements of the Shahed-136 fuselage. There are also instructions on the defects of products and the final assembly of the drone.

Find out more about the Shahed-136 production technology here.

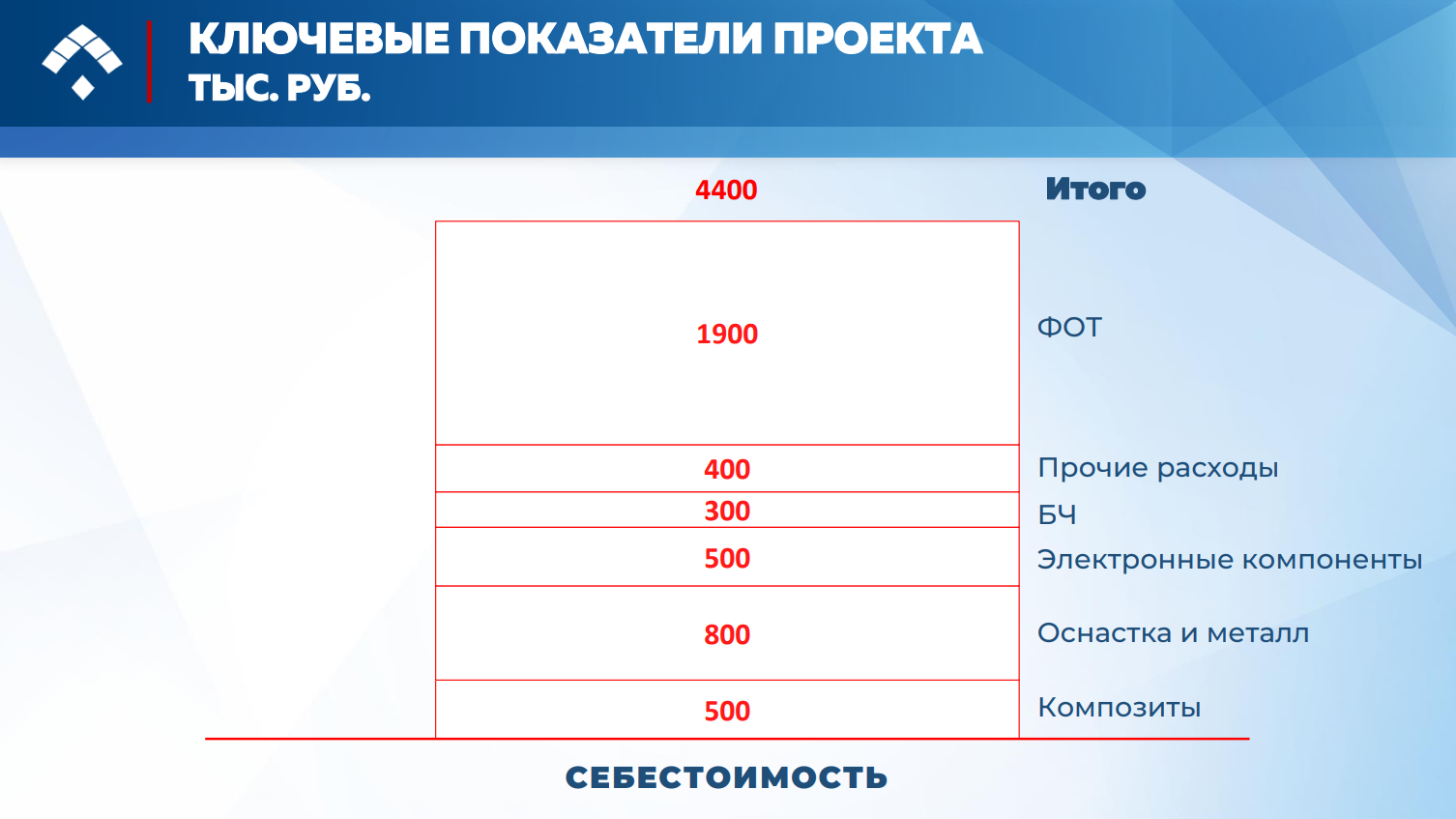

It is worth noting that in one of the presentations devoted to the financial planning of the production of Shahed-136 drones in Russia, the proportions of costs for different parts of production are indicated in the list for one drone.

According to this presentation, if fully localized, the expected cost of production of the drone will be RUB 4.4 million ($48,800). The costs are distributed as follows:

- Wage fund – RUB1.9 million

- Other expenses – RUB 400,000

- Warhead – RUB 300,000

- Electronic components – RUB 500,000

- Rigging and metal – RUB 800,000

- Composites – RUB 500,000

Moreover, the cost of sale, or the price at which they will be transferred to the customer, will be RUB14.9 million ($165,500). Probably, such a gap is due to mortgage payments for licensed production, additional costs, and investments in the enterprise.

Personnel Training and Workforce Involvement

According to the agreement concluded in November 2022, the Russian side should have received a full set of production documentation and a training course for specialists. For personnel training, 300,000 man-hours of training were provided in Iran and another 300,000 in Russia, on the territory of Alabuga.

From April 4 to April 8, the Russian delegation once again visited Iran. There, specialists in avionics and fuselage production, as well as IT specialists, organized training for employees.

The documents mention the issuance of secure communications equipment to key executives to establish Alabuga-Tehran constant contact.

Working staff

According to the information in the presentation regarding the formation of working personnel for production, the company has already launched the first shift for the assembly of drones between April and May 2023.

The plant is designed for round-the-clock operation in three eight-hour shifts. Each shift has a staff of 882 employees (810 for the first half of 2023).

The project assumes that the enterprise will operate 365 days a year. It is noted that the weekends are officially observed, but “work continues with increased pay for working specialties and students.”

The mention of students most likely concerns the ‘Alabuga Politech’, an engineering STEM college that prepares Russian and foreign students for technical specialties. The college itself does not hide the fact that training includes the active involvement of students in work at local enterprises.

This information is confirmed by an article published in June 2023 by Russian ‘Novaya Gazeta’, which reported that 15-17 years old children—students of ‘Alabuga Politech’—were involved in the production of Shahed-136 drones.

In particular, we are talking about students from Africa and Asia: Uganda, Ethiopia, Tanzania, Nigeria, and Pakistan. In the staff list at the disposal of journalists, they were labeled as ‘mulattoes,’ ‘tajiks’ and ‘specialists.’

The same terminology was also seen in the documentation of the Russian enterprise, which discussed the problem of hiring employees.

“Low Mulatto module wage bill, candidates refuse due to low salary,” the document says.

According to the publication, students involved in the work at the plant receive a salary in the range of RUB 30-40,000, depending on the implementation of the plan ($330-430). In addition, overtime is not really compensated for in any way.

Poor pay, as well as the remoteness of the enterprise, is the reason for the shortage of personnel among professional specialists.

Logistics from Iran

Logistics for the transfer of technology and finished products, as well as financial transactions, are carried out through the Iranian intermediary company Sahara Thunder, which the Prana Network hacker group links directly to the Islamic Revolutionary Guard Corps.

Additionally, the files contain invoices and a contract detailing the supply of various equipment and raw materials, such as steel and nickel, which were registered in the UAE by Generation Trading FZE for tens of millions of dollars.

According to the documents, in 2023 it was planned to deliver 2000 sets of spare parts from the ‘friendly country’ to Alabuga for a total amount of RUB 17 billion, or $199.6 million (here and then the average annual exchange rate of the RUB to the USD is used in 2023: 85.16: 1), as well as ‘equipment and technologies’ for a total amount of RUB 102 billion, or $1.197 billion.

To supply components and equipment to Alabuga from Iran, which is disguised in documents as Ireland, three routes were developed within the so-called North-South transport corridor: Trans-Caspian, Western, and Eastern.

The Trans-Caspian route provides for the active use of sea transportation through the Caspian Sea with the involvement of Russian, Iranian, Kazakh, Turkmen, and Azerbaijani ports:

- Russia (Astrakhan, Olya, Makhachkala)

- Iran (Anzali, Nowshahr, Amir Abad)

- Kazakhstan (Aktau, Kuryk)

- Turkmenistan (Turkmenbashi)

- Azerbaijan (Alat)

The Western route is completely land and provides for the transportation of goods from Iran to the Russian Federation through Azerbaijan. The route is as follows: Qazvin – Rasht – Astara – Baku – Samur – Makhachkala – Astrakhan.

The Eastern route is also overland and crosses Turkmenistan and Kazakhstan. The route is as follows: Gorgan – Ak-Yayla – Bereket – Zhanaozen-Mangystau – Beyneu – Makat – Atyrau – Astrakhan.

From the documents, it is known about the use of the Trans-Caspian route: from the port of Amir Abad by sea, goods are delivered to the port of Makhachkala, from where they are transported to their destination by road or railway.

For delivery by sea, standard 20 or 40-foot containers are used, into which four or eight boxes are loaded, respectively. Later, boxes are transferred to trucks or rail transport.

The cost of delivering one box is estimated at RUB 82-90,000 (approximately $960-1050), and the terms are 16-24 days depending on the type of transport and route chosen. At the same time, most of the cost is transportation by sea.

Initially, Sarmat LLC, Edwans Shipping Group, and VTS-Expedition LLC were considered for the organization of sea transportation. However, later, Eurasia Shipping LLC was chosen, which organized the transportation of large shipments of goods (50 40-foot containers) from the Iranian port of Amir Abad to Makhachkala.

It is noteworthy that this company has ties with the Ministry of Defense of the Russian Federation through an intermediary company. Eurasia Shipping Company is directly managed by Spetstranslizing JSC, whose CEO is Anton Filatov (ITN 772443028394), who was the CEO of Oboronlogystika Group of Companies LLC and the founder of NII SSAU JSC.

Oboronlogystika is a logistics company created in the structure of the Ministry of Defense of the Russian Federation, the task of which is “to ensure the needs of the Ministry of Defense of Russia in the field of transportation, storage and production of military and special-purpose products.” In particular, this company is determined by being the sole provider of transport services for the Ministry of Defense of the Russian Federation for the delivery of goods to the temporarily occupied Crimea, the Kaliningrad region, the Arctic zone, and the Far Eastern region.

The NII SSAU JSC is the Scientific Research Institute of Communication, Automation and Control Systems, which proudly reports on its page that “all developments are documented in accordance with government standards, work is carried out under the control of the military mission of the Ministry of Defense of the Russian Federation.”

Eurasia Shipping owns only one ship – ‘Sulak’ (IMO: 9462859). Although it is a relatively small general-purpose cargo ship, it is capable of carrying a certain number of containers.

Since in the Caspian Sea, according to monitoring services, there are no specialized container ships, it is likely that ‘Sulak’ is involved in the transportation of goods in the interests of Alabuga. In support of this assumption, it is noteworthy that, according to the historical movement records on marine monitoring services, the ‘Sulak’ vessel conducted transportation operations in the Black and Mediterranean Seas from 2019 to 2022. However, in December 2022, it was redirected to the Caspian Sea and has since been engaged in transportation between Russian and Iranian ports, with the exception of one visit to the Kazakh port in May 2023.

Project Funding

Based on the data from the published documents, in November 2022, an agreement was concluded between the Russian Federation and Iran to supply Alabuga with kits for assembling 6,000 drones and pay for the transfer of technology, software, equipment, and personnel training for a total amount of RUB 108.5 billion ($1.75 billion). Of these, RUB 72 billion, with a 50% prepayment, was accounted for drones purchasing, and RUB 36.5 billion was designated for the acquisition of the license.

At the same time, according to another document, in 2023 Alabuga had to pay RUB 17 billion, or $199.6 million, as well as for the purchase of “equipment and technologies” totaling RUB 85 billion ($997.5 million) without VAT.

From the documents obtained, it is not entirely clear how these two amounts intersect, so we cannot make definitive statements about the exact sum that the Russians were required to transfer to the Iranians for setting up production at the end of 2022 and throughout 2023. However, based on the available documents, it can be inferred that it falls within the range of RUB 102-210.5 billion ($1.197-2.465 billion).

Given the substantial amount of money involved and the fact that both countries are under sanctions, they have resorted to rather non-standard payment methods, including barter. Consequently, several documents (1, 2, 3) have been published, demonstrating at least two instances of transferring shipments of gold bars from Alabuga Machines to the Iranian company Sahara Thunder, which serves as an intermediary in this scenario.

A total of 3,856,198 grams (3.85 tons) of gold in the ingots were transferred in the two transactions, totaling $224.8 million. Which, however, obviously does not cover the full cost of the deal.

Technology exchange

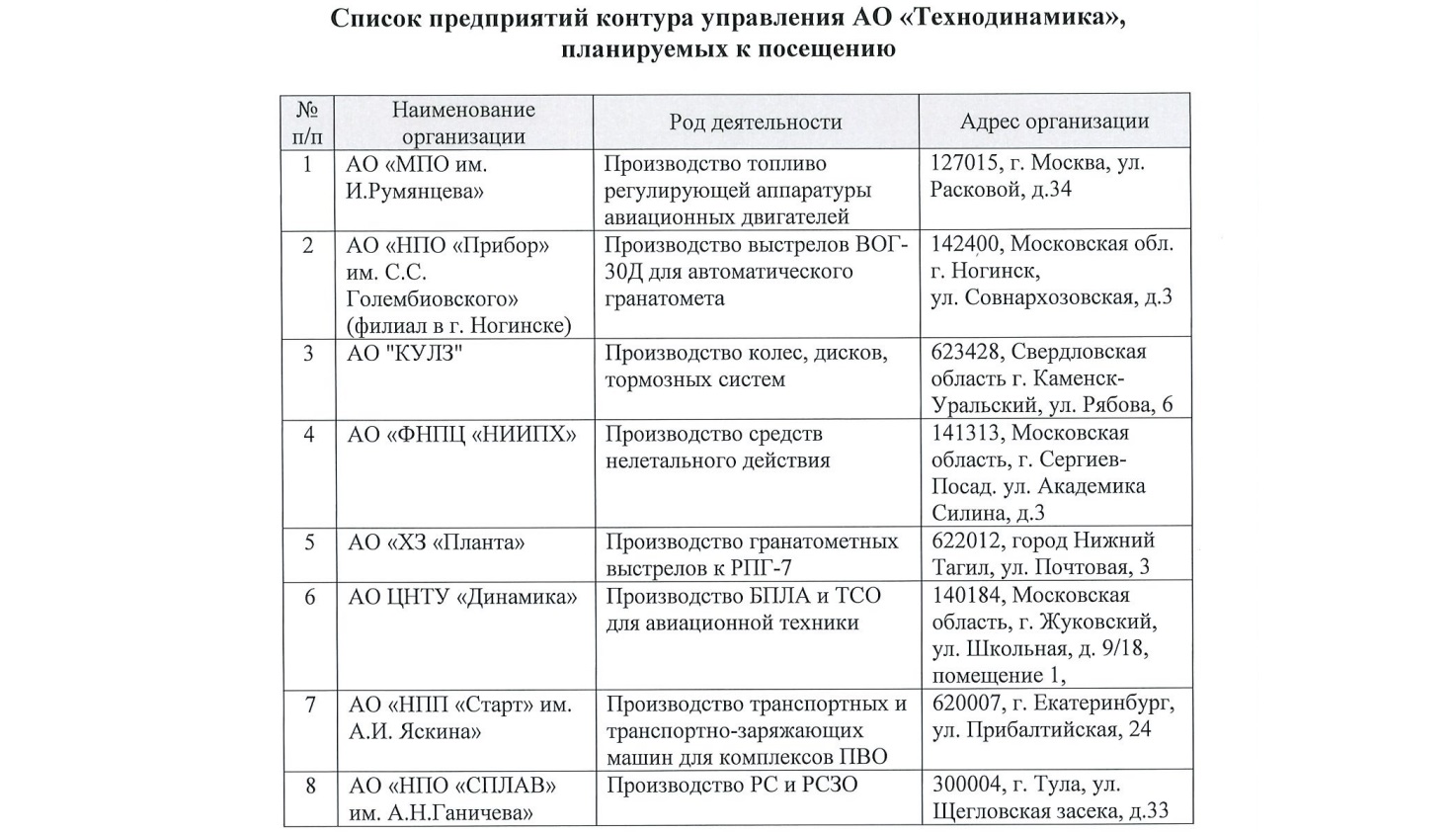

It is likely that other forms of barter were involved in the deal. For example, during or after the Iranian delegation’s visit to the enterprises of the Technodinamika holding (formerly Aviation Equipment) as part of the Rostec state corporation, which took place on March 5-13, 2023.

However, it is also possible that the purpose of the visit was not to familiarize themselves with the technologies necessary for them, but to inspect Russian enterprises that could be involved in the production of Shahed-136 localized components.

It is also worth mentioning that Iran confirmed the agreement to receive Mi-28 attack helicopters, Su-35 fighters, and Yak-130 training aircraft from Russia.

Localization of New Drone Models

The interests of the Russian military-political leadership in Iranian drone production extend beyond just the Shahed-136. Among the documents found are details concerning the exploration of issues related to the release of more advanced drone models, which have only been presented by Iran in recent years.

The plans involve the localization of drones equipped with a jet engine, Target Acquisition System, relay drones and reconnaissance UAVs.

Between April 4 and April 8, 2023, the Russian delegation visited Iran. One of the goals of this trip was to demonstrate the capabilities of “boats 236 with seeker, 236 jet, 107 (reconnaissance/gift).” In other documents, they also pass under other ciphers such as MS-236, MS-237 and 107V/S.

According to the ciphers, the documents referred to Shahed-236 with an optical sensor, Shahed-237 with a jet engine, and a Shahed-107 reconnaissance drone.

According to the report, which was posted by representatives of the delegation after the completion of the trip, the work of the above drones was studied.

The authors of the document note that in April 2023, the Russian plant created all the necessary conditions for localizing the production of the above drones.

It is assumed that the adaptation of production for the release of new samples of drones will take place “at the lowest cost and in a short time,” since it will be carried out on the same lines as Shahed-136 (fuselage, engine, avionics).

The estimated cost of drones (probably for the Russian Federation) was also mentioned:

- MS-236 with seeker – $900,000

- Jet M-237 – $1.4 million

- 107 reconnaissance/strike – $460,000

According to other records, for the normal operation of the controlled strike drone “MS-236” (model with seeker), the release of a version of the Shahed-236 drone with an internal combustion engine and a communication relay station can also be established, which would increase the range of operation.

You can read more about the new drones in the article here.

It is obvious that, subject to the approval and conclusion of new contracts, the production of the drones shown above in Russia will take place for a long time as part of a large-site assembly of ready-made Iranian components.

In addition, the question of the feasibility of localizing reconnaissance drones of the Shahed-107 series remains open in the presence of similar samples in the service of the Russian Federation.

We express our gratitude for the help in writing the material for Dmytro Shumlyansky!

SUPPORT MILITARNYI

Even a single donation or a $1 subscription will help us contnue working and developing. Fund independent military media and have access to credible information.

Центр ініціатив ПЖ

Центр ініціатив ПЖ

Vadim Kushnikov

Vadim Kushnikov

Андрій Тарасенко

Андрій Тарасенко

Юрій Юзич

Юрій Юзич

Віктор Шолудько

Віктор Шолудько

Роман Приходько

Роман Приходько

Андрій Харук

Андрій Харук

Yann

Yann

СПЖ "Водограй"

СПЖ "Водограй"